Content

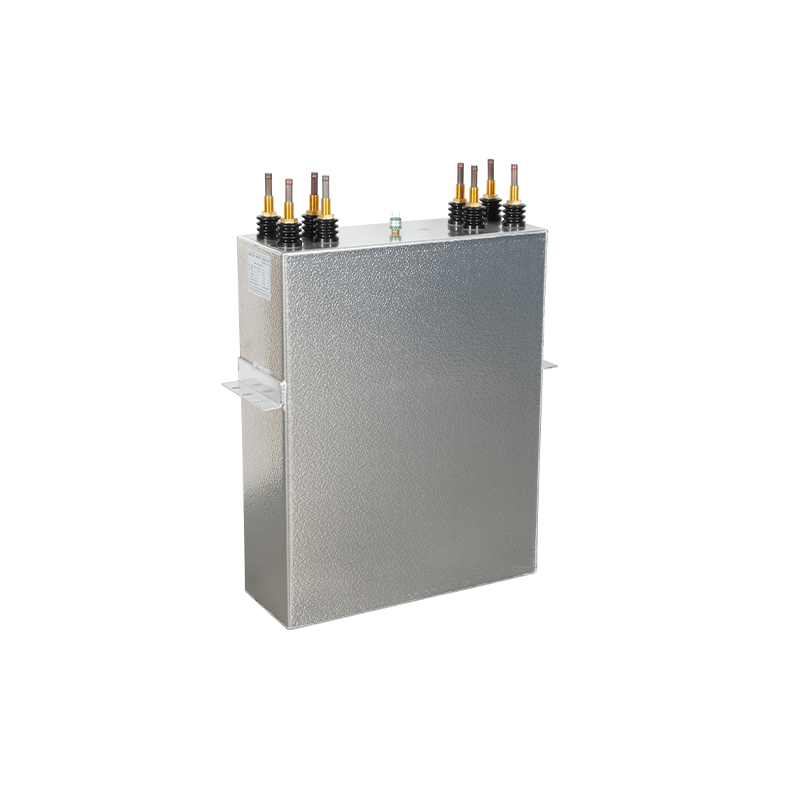

Water Cooling Capacitors are specialized electrical components designed to handle high power and dissipate heat efficiently in industrial and commercial applications. They play a crucial role in maintaining system stability, reducing thermal stress, and extending the lifespan of high-frequency equipment. These capacitors are often used in environments where air cooling is insufficient, and precise temperature control is required to ensure optimal performance. Understanding their design, applications, and benefits is essential for engineers, technicians, and procurement professionals who work with advanced industrial systems.

Selecting a trustworthy manufacturer is vital to ensure quality and performance in water cooling capacitors. A reliable water cooling capacitor manufacturer offers technical expertise, consistent production standards, and quality assurance processes. When evaluating manufacturers, businesses must consider experience, compliance with industrial standards, and the ability to provide technical support. High-quality factories invest in research and development to produce capacitors capable of handling demanding industrial applications while maintaining competitive pricing and low defect rates.

| Manufacturer Experience | Years in capacitor production |

| Production Capacity | Units per month |

| Technical Support | Availability and responsiveness |

| Certifications | ISO, CE, RoHS |

| Defect Rate | Percentage of faulty units |

Many industries require tailored solutions that standard capacitors cannot provide. Custom water cooling capacitor services enable businesses to obtain capacitors that meet specific voltage, current, and thermal requirements. Customization can include modifications in capacitor size, cooling channel design, dielectric material selection, and enhanced thermal dissipation. Factory customization ensures compatibility with specialized industrial systems and reduces the risk of component failure. Working closely with a manufacturer allows engineers to optimize the capacitor for maximum efficiency, safety, and performance.

| Custom Feature | Application |

| Voltage Rating | High-power industrial systems |

| Dielectric Material | Enhanced thermal resistance |

| Cooling Channel | High-efficiency water flow |

| Physical Size | Space-limited installations |

The production process of water cooling capacitors involves multiple precise stages, each critical to ensuring reliability and performance. Water cooling capacitor production process includes component selection, assembly, testing, and quality assurance. High-precision machines handle dielectric layering, electrode placement, and enclosure assembly. Rigorous testing ensures that each capacitor meets electrical, thermal, and mechanical specifications. Understanding this process allows buyers and engineers to appreciate the level of quality control and technological expertise invested in every unit.

| Production Stage | Key Activity |

| Material Prep | Selecting dielectrics and electrodes |

| Assembly | Layering, bonding, and enclosure placement |

| Testing | Electrical, thermal, and pressure tests |

| Quality Control | Inspection of performance and safety |

Industries that operate high-frequency equipment require capacitors capable of handling rapid voltage and current changes without overheating. High-frequency water cooling capacitor manufacturers specialize in producing capacitors designed for these demanding applications. These capacitors feature optimized cooling, low ESR (Equivalent Series Resistance), and high ripple current capacity. They are widely used in renewable energy inverters, industrial drives, and advanced electronic systems. Proper selection ensures energy efficiency, reduces downtime, and enhances overall system performance.

| Specification | Performance Benefit |

| Low ESR | Reduces heat in high-frequency operation |

| High Ripple Current | Improves system stability |

| Optimized Cooling | Extends capacitor lifespan |

| Material Quality | Ensures reliability under heavy load |

Selecting the right water cooling capacitor and managing its installation process are crucial steps for industrial success. Water cooling capacitor purchasing guide helps buyers understand what to consider before purchase, including electrical requirements, thermal constraints, and factory credibility. Once purchased, proper installation ensures optimal performance and safety. Coordinating with factory engineers and following technical manuals reduces installation errors and extends the operational life of capacitors.

| Purchase Step | Key Consideration |

| Factory Selection | Experience, capacity, quality |

| Specification Check | Voltage, current, frequency |

| Installation | Cooling connection, electrical wiring |

| Initial Testing | Thermal and electrical validation |

A water cooling capacitor is designed to handle higher power and dissipate heat efficiently through a liquid cooling system, unlike standard capacitors which rely on air cooling. This results in improved performance, reliability, and longer lifespan, particularly in high-frequency and industrial applications.

Selecting a reliable water cooling capacitor manufacturer involves evaluating production capacity, quality assurance processes, certifications, and technical support. Requesting sample testing and reviewing factory compliance with industry standards ensures that you receive high-quality capacitors suited to your specific application.

Yes. Custom water cooling capacitor services allow customization of voltage, current, dielectric materials, and cooling channels. This ensures that capacitors meet specific industrial demands while maintaining efficiency, safety, and longevity.

The water cooling capacitor production process includes material preparation, precision assembly, thermal and electrical testing, and quality inspection. Each stage ensures the capacitor performs reliably under high-power and high-frequency conditions.

High-frequency water cooling capacitor manufacturers produce capacitors specifically for high-frequency equipment, ensuring low ESR, high ripple current handling, and effective thermal management. These capacitors enhance efficiency and stability in applications such as inverters, power supplies, and industrial drives.

Contact Us

News center

information

Tel: +86-571-64742598

Fax: +86-571-64742376

Add: Zhangjia Industrial Park, Genglou Street, Jiande City, Zhejiang Province, China