Content

In the world of power electronics, the stability and efficiency of a system often hinge on its most fundamental components. Among these, the DC Film Capacitor stands out as a critical element for filtering, energy storage, and snubbing applications. For engineers and procurement specialists, selecting the right capacitor and a reliable DC Film Capacitor Manufactory is paramount to ensuring long-term performance and reliability. This comprehensive guide delves into the specifics of DC film capacitors, their applications, and what to look for in a manufacturing partner, drawing on the four decades of expertise from Jiande Antai Power Capacitor Co., Ltd.

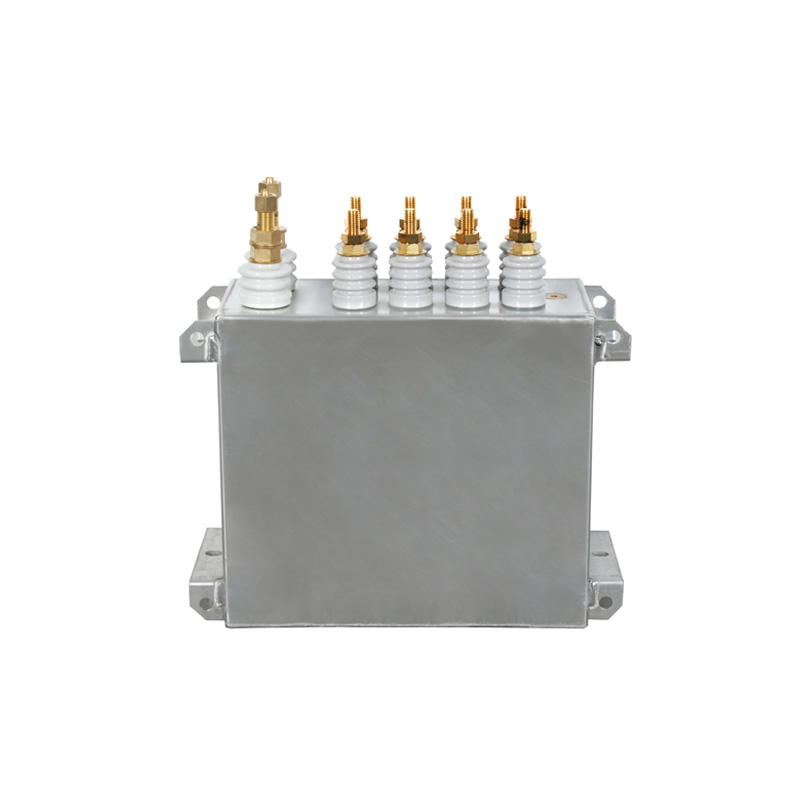

DC film capacitors are passive electronic components that store and release electrical energy in DC circuits. They are constructed using a thin plastic film as the dielectric medium, which is metalized and wound into a compact cylinder. Their design makes them exceptionally suited for handling high voltages and currents with low losses and long service life.

These capacitors are specifically designed to sit in the DC bus of power conversion systems, where they smooth out the rectified voltage and handle high ripple currents.

In variable frequency drives (VFDs), these capacitors are crucial for suppressing electromagnetic interference (EMI) and ensuring clean power delivery to the motor.

Partnering with a manufacturer focused on longevity is critical for applications where maintenance is costly or impossible. Jiande Antai Power Capacitor Co., Ltd. leverages 40 years of experience to produce capacitors known for their endurance.

Choosing the right capacitor technology is a fundamental decision. The table below contrasts DC Film Capacitors with other common types.

| Parameter | DC Film Capacitor | Aluminum Electrolytic Capacitor | Ceramic Capacitor (MLCC) |

| Lifespan | Very Long (100,000+ hours) | Medium (1,000 - 10,000 hours) | Long, but can degrade with voltage |

| ESR (Equivalent Series Resistance) | Very Low | Higher, increases with age | Very Low |

| Self-Healing Property | Yes | No | No |

| Ideal For | High Voltage, High Frequency, Long Life | High Capacitance in small size, Cost-sensitive | High-frequency decoupling, Small signal |

As shown, DC Film Capacitors offer a superior lifespan and lower ESR compared to Aluminum Electrolytics, making them ideal for demanding industrial applications. While MLCCs have low ESR, they lack the self-healing property and high current handling of film capacitors.

Off-the-shelf components are not always sufficient. A proficient DC Film Capacitor Manufactory will offer customization to meet specific application demands.

Induction heating systems demand capacitors that can withstand extremely high alternating currents at medium to high frequencies. This is a core specialty of Jiande Antai Power Capacitor Co., Ltd.

Selecting the right manufacturing partner is as important as selecting the component itself. Here are key factors to consider.

A top-tier DC Film Capacitor Manufactory will have significant infrastructure and rigorous quality control.

Experience and innovation go hand-in-hand. A skilled R&D team, like the one at Antai, is essential for developing new solutions and improving existing products to meet evolving market needs, such as creating more efficient high current dc film capacitor for induction heating designs.

The primary advantage is its significantly longer lifespan and higher reliability. Film capacitors can last over 100,000 hours, while electrolytics typically last a fraction of that time, especially under high-stress conditions.

Yes, a professional manufacturer like Jiande Antai Power Capacitor Co., Ltd. specializes in providing customized dc power capacitor solutions, offering a wide range of voltage ratings, capacitance values, and terminal configurations to meet exact application requirements.

It is critical for stabilizing the DC bus voltage, reducing electrical noise, and protecting sensitive components like IGBTs from voltage spikes. This leads to smoother motor operation, improved efficiency, and reduced electromagnetic interference (EMI).

Such a manufacturer focuses on every aspect of production that impacts longevity. This includes sourcing high-purity raw materials, implementing precise manufacturing processes, and designing capacitors with conservative electrical derating, ensuring products that stand the test of time.

Look for a capacitor specifically designed as a high current dc film capacitor for induction heating. Key specifications to check are a high ripple current rating, low dissipation factor (tan δ), and a robust construction that can handle the thermal and mechanical stresses of the induction heating environment.

Contact Us

News center

Feb - 2026 - 24

Feb - 2026 - 17

information

Tel: +86-571-64742598

Fax: +86-571-64742376

Add: Zhangjia Industrial Park, Genglou Street, Jiande City, Zhejiang Province, China